In recent years, zuschneidfelle have gained notable attention across various industries due to their versatility and practicality. Commonly used in tailoring, industrial fabrication, and crafting, zuschneidfelle are special types of cutting mats or surfaces designed to provide precision and protection during cutting tasks. Whether you’re a professional tailor, hobbyist, or industrial manufacturer, understanding zuschneidfelle and their functions can significantly enhance your workflow and productivity.

What Are Zuschneidfelle?

Zuschneidfelle, a German term translating roughly to “cutting skins” or “cutting mats,” refers to high-durability cutting surfaces made from specialized materials such as rubber, leather, synthetic compounds, or high-density plastics. These surfaces are specifically designed to handle repeated cutting without significant wear or damage, while also preserving the sharpness of cutting tools.

Types of Zuschneidfelle

There are several types of zuschneidfelle available on the market, catering to different needs:

Rubber Zuschneidfelle

Rubber-based cutting mats are flexible, self-healing, and ideal for precise cutting tasks. They’re commonly used in tailoring workshops and crafts.

Plastic Zuschneidfelle

These mats are made from high-density polyethylene (HDPE) or polypropylene. They’re suitable for industrial applications due to their durability and resistance to heavy-duty cutting.

Leather Zuschneidfelle

Used in traditional tailoring and shoemaking, leather zuschneidfelle provide a natural surface that is soft yet durable, perfect for sharp instruments.

Composite Zuschneidfelle

These cutting surfaces blend materials like rubber and plastic for added toughness and multi-purpose use, popular in both small workshops and large production units.

Common Applications of Zuschneidfelle

Zuschneidfelle are used across various sectors for tasks that require accurate, clean cutting. Some of the key applications include:

Tailoring and Garment Manufacturing

Tailors rely on zuschneidfelle to cut fabrics with precision while avoiding damage to workbenches or dulling scissors and rotary blades.

Leather Crafting

Artisans in leatherworking use zuschneidfelle to protect tools and maintain consistent cutting lines when working on belts, wallets, shoes, and bags.

DIY Crafting and Quilting

Crafters and hobbyists benefit from these mats for scrapbooking, quilting, and intricate papercraft projects.

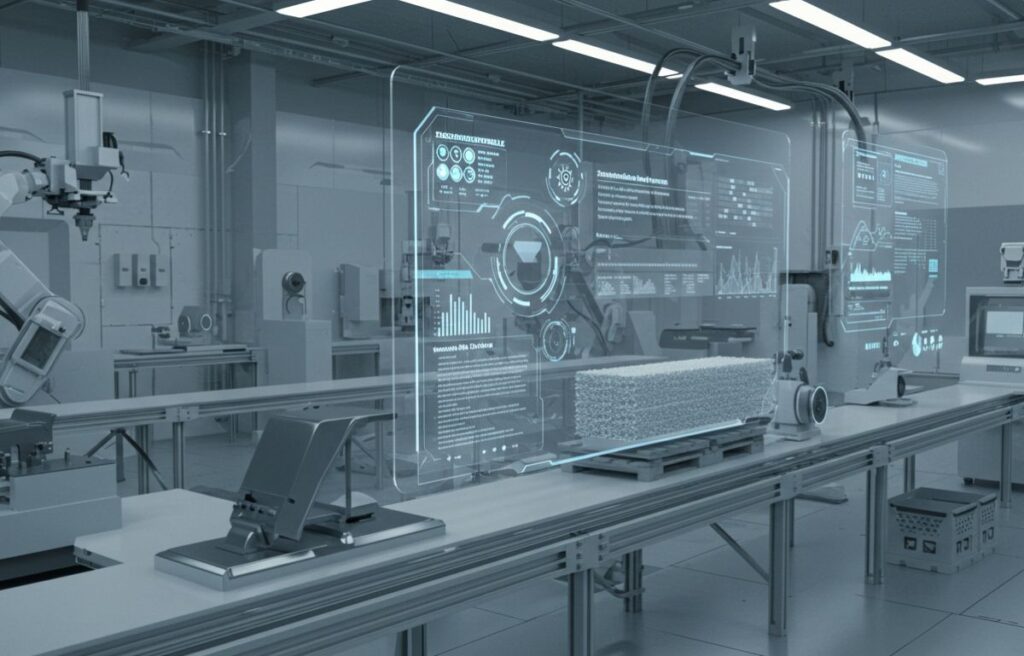

Industrial and Mechanical Cutting

Factories utilize zuschneidfelle in metal, plastic, or composite material cutting. Their durability helps handle industrial blades and robotic arms.

Key Benefits of Zuschneidfelle

The advantages of using go beyond basic protection. Here’s how they add value:

Precision Cutting

A high-quality zuschneidfell provides a stable, non-slip surface that ensures your cuts are exact, which is especially important in pattern making.

Tool Preservation

Blades tend to stay sharper longer when used on due to the soft-yet-tough material composition, reducing maintenance costs.

Surface Protection

Workbenches, tables, or floors remain intact without scratches, gouges, or cuts when are in use.

Long-Term Durability

Many feature self-healing properties, allowing the surface to “bounce back” after cuts and extend the mat’s lifespan.

Eco-Friendly Options

Some manufacturers offer environmentally friendly made from recycled rubber or biodegradable compounds.

Choosing the Right Zuschneidfell

When selecting a zuschneidfell for personal or professional use, consider the following factors:

-

Size and Thickness: Larger mats suit industrial tables, while smaller ones are ideal for crafting.

-

Material Composition: Choose rubber for flexibility, plastic for durability, and leather for traditional aesthetics.

-

Self-Healing Properties: Helps extend usability and ensures clean cutting lines.

-

Non-Toxic and Odor-Free: Especially important in closed environments like classrooms or small studios.

Maintenance and Care for Zuschneidfelle

To get the most out of your zuschneidfell, proper maintenance is essential:

-

Clean Regularly: Use a damp cloth to remove residue and dust.

-

Avoid Extreme Heat: Exposure to high temperatures may warp plastic or rubber surfaces.

-

Store Flat: Always store your zuschneidfell flat to avoid curling or deformation.

-

Rotate Frequently: If possible, use different sections of the mat to ensure even wear over time.

Trends and Innovations in Zuschneidfelle

As the demand for crafting tools increases, innovations in continue to emerge:

-

Antibacterial Coatings: For hygiene in textile factories and schools.

-

Custom Printed Grids: Integrated measurement guides help improve accuracy.

-

Smart: Emerging prototypes include digital interfaces that sync with cutting software for precision guidance.

-

Reinforced Layers: Multi-layered mats can withstand both rotary and industrial blade use without wear.

Sustainability and the Future of Zuschneidfelle

With increasing focus on sustainable practices, zuschneidfelle manufacturers are developing more eco-conscious solutions. Recycled rubber and biodegradable options are gaining popularity among environmentally aware consumers.

In the future, we may see smart integrated with sensors to track blade pressure and frequency of use—offering insights to improve efficiency and tool longevity.

Conclusion

Zuschneidfelle are indispensable tools for anyone working with cutting tasks, from industrial professionals to hobbyist crafters. Their versatility, durability, and ability to maintain cutting precision make them a wise investment for efficient and safe workspaces. As innovations continue to shape the future of , users can expect even more enhanced features focused on sustainability, technology integration, and improved performance.

By choosing the right zuschneidfell for your needs and maintaining it properly, you can elevate your craft or production process with ease and precision.